| Máy nạp rom, Jig test |

| » | Máy nạp rom đa năng |

| » | Máy nạp Gang đa năng |

| » | Máy nạp rom on-board |

| » | Máy nạp chuyên biệt |

| » | Hệ thống nạp tự động |

| » | Phụ kiện đế nạp socket |

| » | Xoá Rom, kiểm tra IC |

| » | Sao chép ổ cứng, thẻ nhớ |

| » | Jig test ICT/FCT/DIP-pallet |

| Đo lường và kiểm tra |

| » | Dao động ký oscilloscope |

| » | Thiết bị viễn thông, RF |

| » | Bộ thu thập dữ liệu |

| » | Đồng hồ vạn năng số |

| » | Máy phát xung, đếm tần |

| » | Máy đo LCR, linh kiện |

| » | Bộ đổi nguồn, tải điện tử |

| » | Kit đào tạo, thực hành |

| Các công cụ sản xuất |

| » | Máy khò, mỏ hàn thiếc |

| » | Tủ sấy, tủ môi trường |

| » | Dây chuyền SMT Line |

| » | Thiết bị sản xuất PCBA |

| Thiết bị, công cụ khác |

| » | Thiết bị Automotive |

| » | Đo lực, cơ điện khác |

| » | Thiết bị quang học |

| Linh phụ kiện Điện tử |

| » | Vi điều khiển họ 8051 |

| » | Nuvoton ARM Cortex-M |

| » | Nuvoton ARM7/9 Soc |

| » | Chip phát nhạc, audio |

| » | Wireless RF IC, Tools |

| » | Vật tư hàn, rửa mạch |

| e-Shop thiết bị, vật tư |

|

|

|

Hiện tại có 0 khách và 0 thành viên đang online.

Bạn là khách. Bạn có thể đăng kí bằng cách nhấn vào đây |

OUR PARTNERS

(Products Line-Card)

|

| |

Danh mục nội dung: Chuyên mục chính/3. Hệ thống, công cụ và thiết bị phát triển sản xuất điện tử/3.3. Công cụ hàn thiếc, khò IC và gia công PCB lô nhỏ (Soldering tools, rework system)

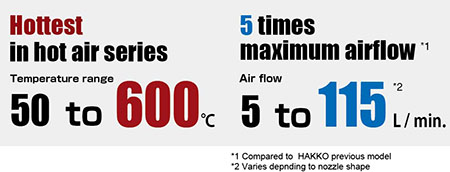

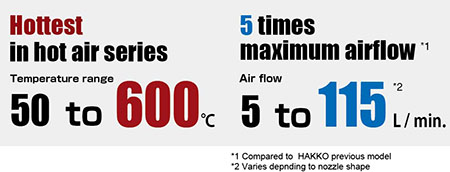

| | | | | ◊ Đặc điểm chính: | | - 670W high power and large volume hot air improves work efficiency.

- Vacuum pick up function for easy and safe removal of components.

- Possible to make a simple thermal profile by Chain Presets function

- máy khò với dải điều chỉnh công suất lớn 670w tích hợp chức năng nhặt hút chân không và thiết lập đồ thị tiện lợi |

|

|

High power and large air volume

Further evolution of SMD rework stationHigh power and large volume hot air for quick removal of components A tool that can provide powerful hot airflow for repairing high heat capacity circuit boards that require high blow volume and high output, and sufficient hot airflow for appropriate blow volume and high output for high-density mounting substrates.

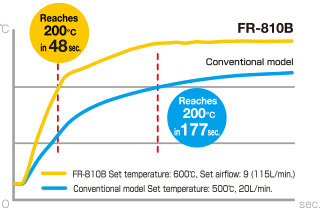

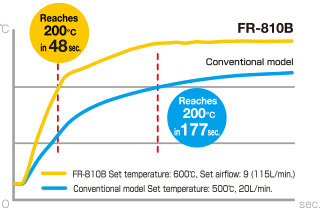

Efficiency improvement The high volume airflow and high output of FR-810B make it possible to perform the same work in only one-third of the time required when using a conventional model. This reduces the thermal impact on boards and components.

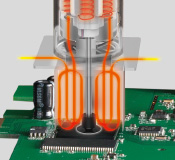

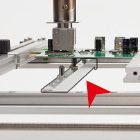

* Examination of time taken for connector sections soldered onto a ceramic board to be heated to 200°C with maximum temperature and airflow settings selected. * Single nozzles with an approximately 4mm diameter were used. Improvements of FR-810B On top of the features of FR-810, high power and large air volume, the new functions of vacuum pickup and pickup indicator have been given to FR-810B. The 2 new functions make it possible to remove a component without damaging PWB. | ・New type of nozzles for improvement of temperature characteristics | The new nozzle improves work efficiency with uniform heating by hot air convection inside the nozzle which is created due to vents on the nozzle top. (Only with BGA nozzle)

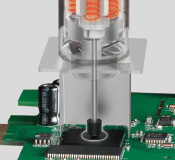

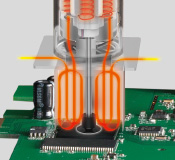

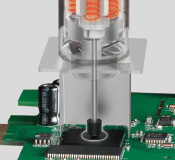

|  | | ・Vacuum pickup function | The vacuum pickup function is to pick up a component with a suction pad and vacuum. It will pick a component only after the hot air melts solder joints.

This can avoid an error to peel off the land by removing a component with excessive force.

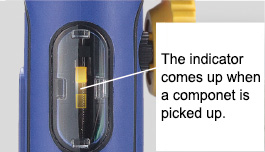

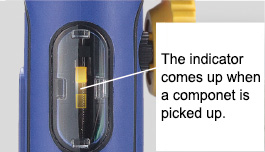

|  | | ・Pickup indicator | By pre-setting pickup function, a component can be picked up automatically when solder is melted. At the same time, the indication comes up and the moment of picking up will be visible. Even a component and solder joints can not be seen as covered by a nozzle, easy and safe picking up is possible.

|  |

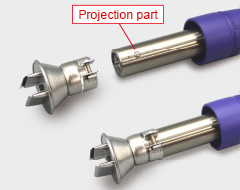

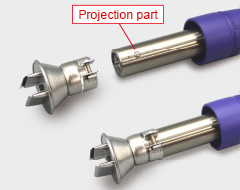

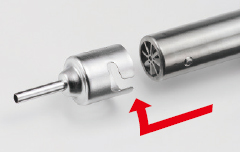

Use conventional HAKKO nozzles Align the projection part, attach the conventional nozzle to the heater pipe.

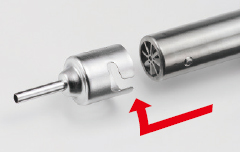

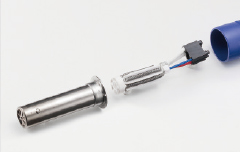

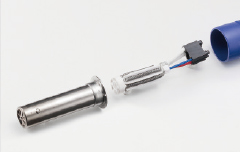

*The heater pipe of HAKKO FR-810 (discontinued) has two projection parts. In order to use the conventional nozzle, put the conversion adaptor on the heater pipe that was included in your purchased HAKKO FR-810 as one of standard accessories. Click here for details. Simple nozzle removal and easy maintenance Nozzles can be quickly changed for many different types of components. In addition, conventional nozzles are compatible. Heaters can also be easily and securely replaced. | Quick-change N51 nozzles | Simple heater replacement |  |  | | Simple, tool-free removal and attachment. | Simply remove four screws to replace heater. |

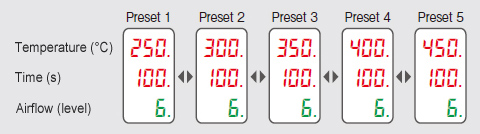

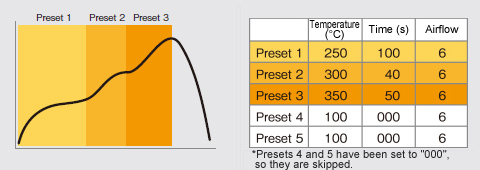

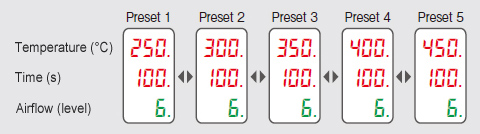

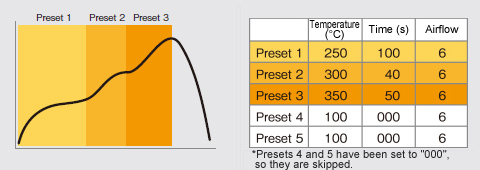

Timer function Timer function is to control the time of operation. This can help to prevent parts from overheating and can improve the overall quality of rework. Chain presets function for making a simple thermal profile The chain presets function is to make a simple thermal profile by combining several preset conditions. (Up to 5 steps) This can improve work efficiency a lot by standardizing work time, avoiding overheating, improving repeatability of operation, and making difficult rework jobs easy.

Auto sleep and auto shutoff features

| - To ensure safety and conserve power, when the handpiece is placed in the handpiece holder, the auto sleep function will be activated and it will start cooling automatically.

- If the handpiece has not been removed from the handpiece holder (e.g. Using it in a rework fixture) and it has been idle for 30 minutes, auto shutoff function will be activated. It will be automatically powered off.

- Access to settings can be restricted by the password function.

|

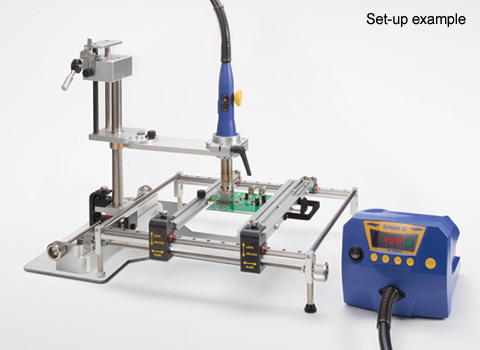

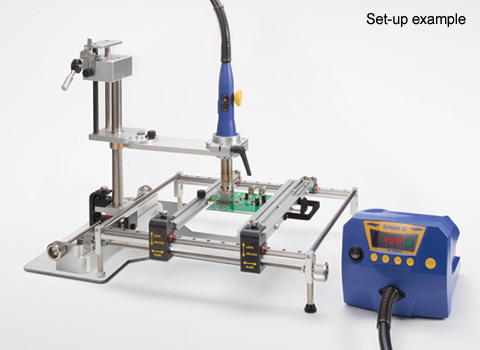

A low cost rework system can be assembled with a bottom heater, a grip fixture, and a board holder.

| Grip Fixture M

Recommended if a bottom heater is not required or in case of use of a bottom heater other than the dedicated model for FR-811.

|  | Board Holder

Makes it easy to set and remove a PWB and to make fine adjustments after setting.

|  | Board Clip

Accepts even irregular-shaped PWB.

|  | Board Support Unit

Supports PWB from underneath to minimize warping.

|

Model No.Packing List |

| FR-810B | Station with handpiece, Nozzle (Φ 4 mm), Handpiece holder, Vacuum pipe control knob L (with screw), Pads (qty 2 each of Ø3 mm, Ø5 mm, Ø7.6 mm), Heat resistant pad, Power Cord, Temperature distribution chart, Instruction manual

|

Model No.FR-810BPower consumptionTemperature range |

AC100V:700W

AC110V:840W

AC120V:820W

AC220V:1,100W

AC230V:1,200W

AC240V:1,300W | | 50 to 600ºC |

・Station Power consumptionAir flowDimensionsWeight | 30W | | 1-9 (5 to 115L/min) | | 160(W)×145(H)×220(D)mm | | 1.5kg |

・Handpiece (Hot air) Power consumptionStandard nozzleTotal lengthWeight AC100V:670W

AC110V:810W

AC120V:790W

AC220V:1,070W

AC230V:1,170W

AC240V:1,270W | | Φ4mm (No.N51-02) | | 250mm | | 180g |

* Total length and weight for handpiece (w/o cord, standard nozzle)

* Airflow capacity is rated as free flowing. Restrictions created by various nozzles may reduce the maximum airflow capacity.

A nozzle (No.N51-02) is supplied with HAKKO FR-810B.

CÁC SẢN PHẨM KHÁC CÙNG NHÀ SẢN XUẤT / OTHER PRODUCTS FROM Hakko |

|

|

| | |

ĐỐI TÁC QUỐC TẾ

Minato, Leap, SMH-Tech, Xeltek, Elnec, Conitec, DediProg, Phyton, Hilosystems, Flash Support Group, PEmicro || Rigol, Tonghui, Copper Mountain, Transcom, APM || Atten, Zhuomao, Puhui, Neoden, Ren Thang, Genitec, Edry, UDK ||

|

ENGLISH

ENGLISH Trang chủ

Trang chủ

FR-810B: SMD Rework System

FR-810B: SMD Rework System